IPOQLOR®

Offline chlorine generator for public pools

IPOQLOR®

Offline chlorine generator for public pools

IPOQLOR®, the cost-saving, powerful and tailor-made chlorine generator

Placed in a machine room, IPOQLOR® produces chlorine from softened water and salt according to the very effective principle of salt electrolysis. Easy to install and use, this solution has been developed for public and commercial pools.

Economical over the long term: salt, the raw material of electrolysis, allows a significant reduction in the costs of transport, storage and handling.

Powerful and tailor-made: Designed to easily integrate with existing installations, the IPOQLOR® generator produces a highly active chlorine solution that can be used in situ.

IPOQLOR®, the cost-saving, powerful and tailor-made chlorine generator

Placed in a machine room, IPOQLOR® produces chlorine from softened water and salt according to the very effective principle of salt electrolysis. Easy to install and use, this solution has been developed for public and commercial pools.

Economical over the long term: salt, the raw material of electrolysis, allows a significant reduction in the costs of transport, storage and handling.

Powerful and tailor-made: Designed to easily integrate with existing installations, the IPOQLOR® generator produces a highly active chlorine solution that can be used in situ.

4 main common chemical treatment drawbacks:

- Risk of accidents linked to the handling storage and transport of chemical products

- Deterioration in chlorine quality over the time

- Operating costs of conditioned chlorine

- Regular and expensive maintenance

4 main common chemical treatment drawbacks:

- Risk of accidents linked to the handling storage and transport of chemical products

- Deterioration in chlorine quality over the time

- Operating costs of conditioned chlorine

- Regular and expensive maintenance

PROCESS

1/ The generator produces a chlorinated solution and pours it directly into a storage tank.

2/ A dosing pump* controlled by an automatic control system feeds the pool according to demand. The treatment of swimming pool is ensured automatically

3/ The pool water is kept disinfected and disinfecting permanently, ensuring comfort and safety for bathers

However, over-sizing of pumps and injection lines may be necessary.

*Automatic control and injection systems already installed on the system are compatible with IPOQLOR®.

PROCESS

1/ The generator produces a chlorinated solution and pours it directly into a storage tank.

2/ A dosing pump* controlled by an automatic control system feeds the pool according to demand. The treatment of swimming pool is ensured automatically

3/ The pool water is kept disinfected and disinfecting permanently, ensuring comfort and safety for bathers

However, over-sizing of pumps and injection lines may be necessary.

*Automatic control and injection systems already installed on the system are compatible with IPOQLOR®.

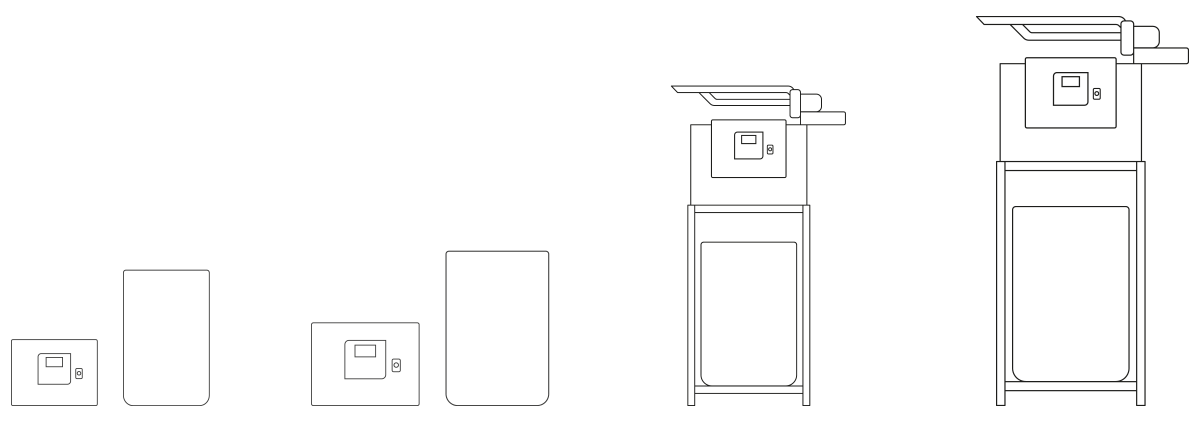

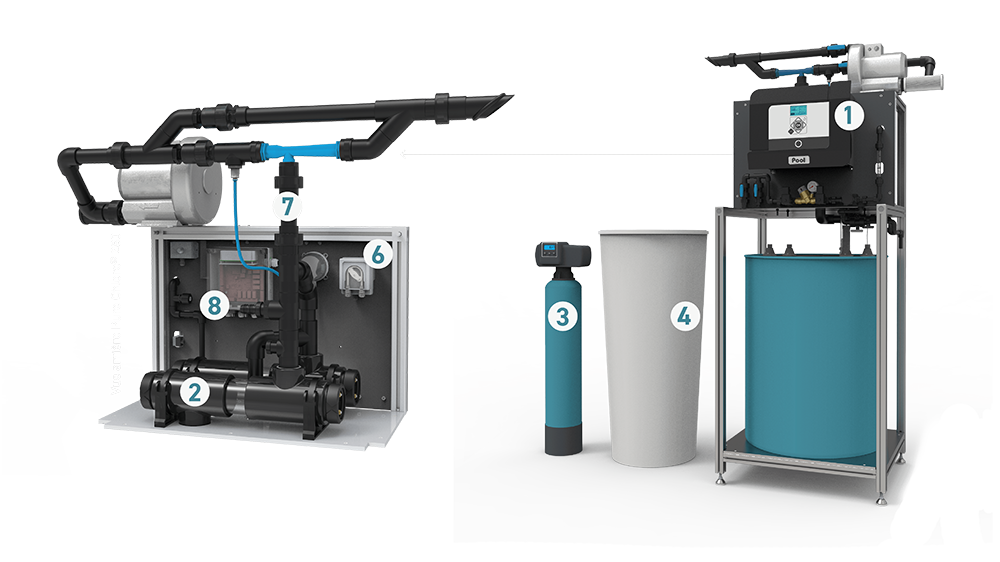

PC 140

1/ CONTROL AND PRODUCTION BOX

Easy to use: The BOOST mode allows to launch an automatic filling program in a natural way or with predefined timetables

Convenient: LED status indicator allows to

check quickly the facility operating properly

(PC280 and PC560).

2/ PRODUCTION CELLS

Long cell lifespan: cell lifespan is estimated at 10 000 operating hours

operating hours, an integrated lamp timer

triggers a written message to check plates

condition.

3/ SOFTENER

High filtration capacity: less frequent

regeneration due to a higher resin volume.

PC 280

4/ SATURATED BRINE TANK

Ease of maintenance: wide box opening to add easily and quickly the maximum salt level.

High storage capacity: to add salt level punctually

5/ STORAGE TANK

UV-treated tank: preserving pure and fresh

chlorine.

suction.

overproduction, the sensor automatically

switches off the system.

sensors to facilitate its maintenance or

replacement.

6/ PUMP

Consumption optimization: pump injects

automatically the perfect brine volume in

production cells

PC 560

7/ HYDROGEN EXHAUST SYSTEM

H2 alarm: if an anomaly is detected, a safety

mode is triggered and automatically switches off the production of chlorine.

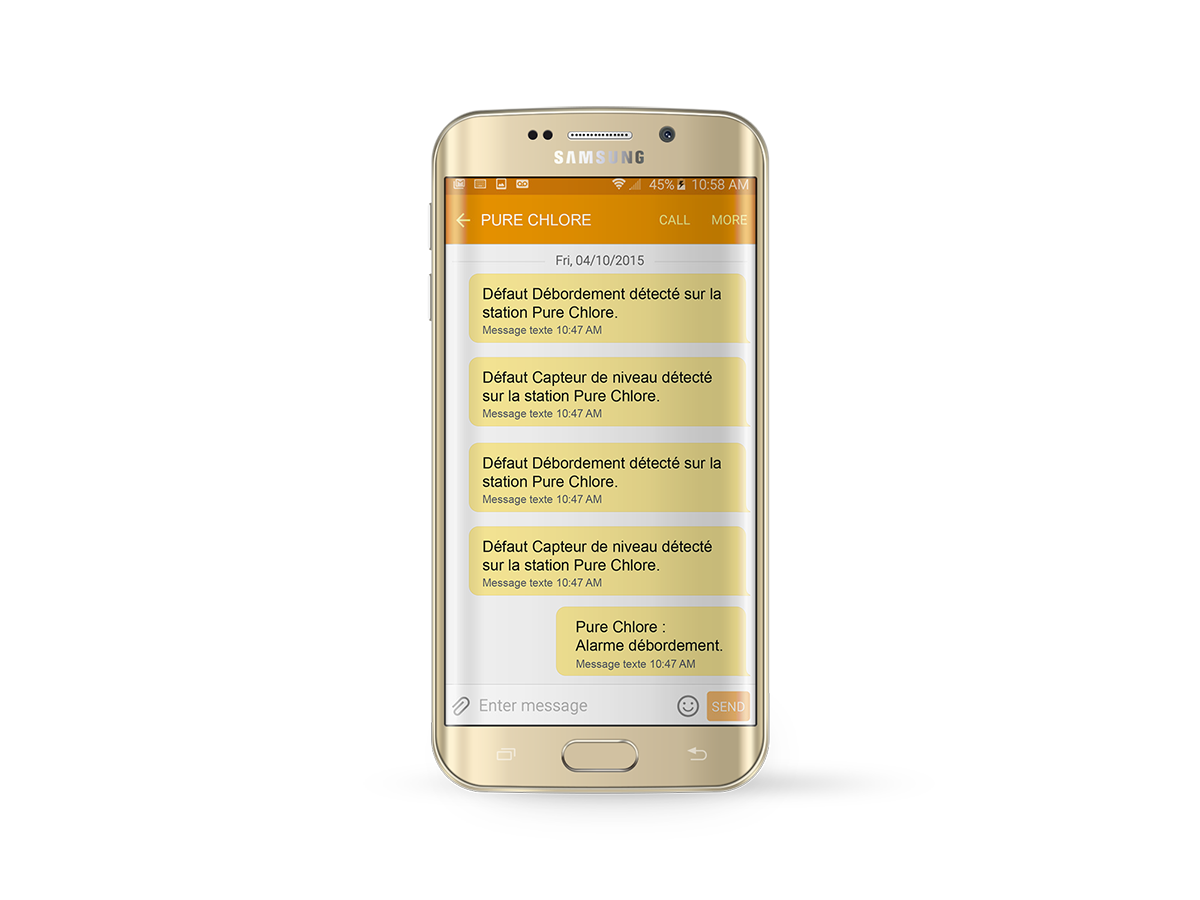

8/ CONNECTIVITY

Real-time remote control:

PC 140

1/ CONTROL AND PRODUCTION BOX

Easy to use: The BOOST mode allows to launch an automatic filling program in a natural way or with predefined timetables

Convenient: LED status indicator allows to

check quickly the facility operating properly

(PC280 and PC560).

2/ PRODUCTION CELLS

Long cell lifespan: cell lifespan is estimated at 10 000 operating hours

operating hours, an integrated lamp timer

triggers a written message to check plates

condition.

3/ SOFTENER

High filtration capacity: less frequent

regeneration due to a higher resin volume.

PC 280

4/ SATURATED BRINE TANK

Ease of maintenance: wide box opening to add easily and quickly the maximum salt level.

High storage capacity: to add salt level punctually

5/ STORAGE TANK

UV-treated tank: preserving pure and fresh

chlorine.

suction.

overproduction, the sensor automatically

switches off the system.

sensors to facilitate its maintenance or

replacement.

6/ PUMP

Consumption optimization: pump injects

automatically the perfect brine volume in

production cells

PC 560

7/ HYDROGEN EXHAUST SYSTEM

H2 alarm: if an anomaly is detected, a safety

mode is triggered and automatically switches off the production of chlorine.

8/ CONNECTIVITY

Real-time remote control:

The effectiveness of chlorine without the disadvantages

The effectiveness of chlorine without the disadvantages

Chlorine is the most powerful disinfectant known on pool market. The IPOQLOR® solution produces a fresh chlorine for in situ use.

EFFECTIVENESS: production of fresh and pure chlorine without alteration, unlike conditioned chlorine which is sensitive to the surrounding factors (light, polluted air, temperature…)

STRENGTH: highly active hypochlorite solution from a low concentration of chlorine. A storage tank allows automatic superchlorination according to the actual pool needs.

HEALTH: high disinfectant power removing almost all chloramines, so harmful to the health of bathers and responsible for unpleasant odors.

RESPECT FOR BATHERS’ HEALTH: no more red eyes, no more itchy skin, no more chlorine odour, no more faded swimwear.

MAINTENANCE SAFETY: removal of all problems due to transport, storage and handling of conditioned chlorine: cartridge masks, explosion hazards, containment of the chlorine storage area.

EASE OF MAINTENANCE: simplified cleaning procedure. A descaling of the cells every 1000 operating hours (depending on use) is sufficient.

COST-SAVING: significant reduction in transport and storage costs: low cost of use, salt is half the cost of conditioned chlorine; Storage in large quantities, drastic reduction in delivery times and constraints related to storage regulations.

EASE OF INSTALLATION: easy embedding with existing installations.

PROTECTION OF EQUIPMENT OVER LONG TERM: the low concentration of the chlorinated solution and the absence of salt in the basin prevent corrosion.

So many reasons to adopt IPOQLOR®!

Chlorine is the most powerful disinfectant known on pool market. The IPOQLOR® solution produces a fresh chlorine for in situ use.

EFFECTIVENESS: production of fresh and pure chlorine without alteration, unlike conditioned chlorine which is sensitive to the surrounding factors (light, polluted air, temperature…)

STRENGTH: highly active hypochlorite solution from a low concentration of chlorine. A storage tank allows automatic superchlorination according to the actual pool needs.

HEALTH: high disinfectant power removing almost all chloramines, so harmful to the health of bathers and responsible for unpleasant odors.

RESPECT FOR BATHERS’ HEALTH: no more red eyes, no more itchy skin, no more chlorine odour, no more faded swimwear.

MAINTENANCE SAFETY: removal of all problems due to transport, storage and handling of conditioned chlorine: cartridge masks, explosion hazards, containment of the chlorine storage area.

EASE OF MAINTENANCE: simplified cleaning procedure. A descaling of the cells every 1000 operating hours (depending on use) is sufficient.

COST-SAVING: significant reduction in transport and storage costs: low cost of use, salt is half the cost of conditioned chlorine; Storage in large quantities, drastic reduction in delivery times and constraints related to storage regulations.

EASE OF INSTALLATION: easy embedding with existing installations.

PROTECTION OF EQUIPMENT OVER LONG TERM: the low concentration of the chlorinated solution and the absence of salt in the basin prevent corrosion.

So many reasons to adopt IPOQLOR®!

A very simple operating principle

A very simple operating principle

1/ A softener feeds the installation with softened water

2/ Saturated brine is obtained on site from softened water

and salt.

3/ The brine is injected into the softened water stream before

the production cell lines.

4/ Softened water and salt are converted into a solution

of sodium hypochlorite (NaClO) according to saltwater

chlorination process.

5/ The solution of sodium hypochlorite is poured, by gravity,

into a storage tank equipped with level detectors. The

production is triggered or stopped automatically depending

on the position of the level detectors in order to constantly

maintain the required stock of solution. The tank capacity

varies depending on the model. Incorporate a free-moving

suction with level sensor.

6/ The hydrogen produced is evacuated to the outside by a

degassing chimney

7/ The control box independently manages the production

of sodium hypochlorite (NaClO). It allows to maintain a

constant supply of solution in order to guarantee, in all

circumstances, the ideal chlorine level in the basin.

automatic chlorine regulation (optional). The injection is

done by a large flow metering pump

9/ SMS Alerts/Remote fleet management.

1/ A softener feeds the installation with softened water

2/ Saturated brine is obtained on site from softened water

and salt.

3/ The brine is injected into the softened water stream before

the production cell lines.

4/ Softened water and salt are converted into a solution

of sodium hypochlorite (NaClO) according to saltwater

chlorination process.

5/ The solution of sodium hypochlorite is poured, by gravity,

into a storage tank equipped with level detectors. The

production is triggered or stopped automatically depending

on the position of the level detectors in order to constantly

maintain the required stock of solution. The tank capacity

varies depending on the model. Incorporate a free-moving

suction with level sensor.

6/ The hydrogen produced is evacuated to the outside by a

degassing chimney

7/ The control box independently manages the production

of sodium hypochlorite (NaClO). It allows to maintain a

constant supply of solution in order to guarantee, in all

circumstances, the ideal chlorine level in the basin.

automatic chlorine regulation (optional). The injection is

done by a large flow metering pump

9/ SMS Alerts/Remote fleet management.

Local service

Local service

IPOQLOR® installation diagram

IPOQLOR® installation diagram

Word of a pro

Word of a pro

“SALT, HALF THE COST OF TRADITIONAL CHLORINE TREATMENT, IS EASILY TO STORE IN LARGE VOLUME“

As soon as I became Beaugency public pool Manager, I did my best to replace the old hypochlorite installation with the more economical PURE CHLORE solution over the long term. Thanks to its great autonomy and to the reduction of the costs generated by its use, I convinced the elected representatives to install PURE CHLORE on 3 fundamental points: the reduction of costs generated, the drastic drop in chloramine levels and the wellbeing brought to the users. For technicians, the installation of PURE CHLORE is a small revolution. Previously, we had to regularly clean and empty the tank, remove the residue or unclog the strainers. Thanks to this generator, maintenance is greatly facilitated. The chlorine ensures a very good disinfection, while avoiding the chloramines, responsible for the unpleasant odor. For example, with the old calcium hypochlorite pellet, we had added two dechlorinators to stay below the permitted standard (0.6 ppm chloramines). By installing PURE CHLORE we had the test by disconnecting one of the two devices. Despite a temperature around 30°C due to a malfunction of the air recirculation system, the water contained only 0.3 ppm of chloramines. This summer, despite the absence of the 2 dechloraminators and the Increased attendance, we stayed within the limit. I am also very pleased with this solution because it has significantly improved water quality. Even after the passage of 400 people a day and without counting the courses of aquabiking which require an overchlorination, the water remains crystalline. The users, themselves, see the difference because their skin is less attacked and their eyes are no longer irritated.

We now only store salt. An additional safety for our technicians who no longer handle dangerous products and no longer wear masks. Beyond the safety aspect, the unique use of salt allows us, every week, to save 70% in consumables. I recommend PURE CHLORE to the other managers of collective swimming pools.

S. COSTA, Director of the Beaugeancy’ public swimming pool, France

“SALT, HALF THE COST OF TRADITIONAL CHLORINE TREATMENT, IS EASILY TO STORE IN LARGE VOLUME“

As soon as I became Beaugency public pool Manager, I did my best to replace the old hypochlorite installation with the more economical PURE CHLORE solution over the long term. Thanks to its great autonomy and to the reduction of the costs generated by its use, I convinced the elected representatives to install PURE CHLORE on 3 fundamental points: the reduction of costs generated, the drastic drop in chloramine levels and the wellbeing brought to the users. For technicians, the installation of PURE CHLORE is a small revolution. Previously, we had to regularly clean and empty the tank, remove the residue or unclog the strainers. Thanks to this generator, maintenance is greatly facilitated. The chlorine ensures a very good disinfection, while avoiding the chloramines, responsible for the unpleasant odor. For example, with the old calcium hypochlorite pellet, we had added two dechlorinators to stay below the permitted standard (0.6 ppm chloramines). By installing PURE CHLORE we had the test by disconnecting one of the two devices. Despite a temperature around 30°C due to a malfunction of the air recirculation system, the water contained only 0.3 ppm of chloramines. This summer, despite the absence of the 2 dechloraminators and the Increased attendance, we stayed within the limit. I am also very pleased with this solution because it has significantly improved water quality. Even after the passage of 400 people a day and without counting the courses of aquabiking which require an overchlorination, the water remains crystalline. The users, themselves, see the difference because their skin is less attacked and their eyes are no longer irritated.

We now only store salt. An additional safety for our technicians who no longer handle dangerous products and no longer wear masks. Beyond the safety aspect, the unique use of salt allows us, every week, to save 70% in consumables. I recommend PURE CHLORE to the other managers of collective swimming pools.

S. COSTA, Director of the Beaugeancy’ public swimming pool, France

You have a project?

Contact our sales department!

purechlore@pool-technologie.fr

You have a project?

Contact our sales department!

purechlore@pool-technologie.fr