THE EFFECTIVENESS OF CHLORINE WITHOUT THE DRAWBACKS!

In-situ chlorine generation by saltwater chlorination

THE EFFECTIVENESS OF CHLORINE WITHOUT THE DRAWBACKS!

In-situ chlorine generation by saltwater chlorination

What is in-situ chlorine generation?

The Pool Technologie in-situ chlorine generators allow you to produce your chlorine on site from salt and softened water, in an economical way and in complete autonomy. This solution provides all the benefits of salt electrolysis without adding any salt to the pool. Indeed, the electrolysis cell is not integrated in the hydraulic circuit but housed in a reactor installed in the technical room. Only a chlorine solution is produced and stored in a secure storage tank. The salt content of the waste water is therefore negligible.

With more than 10 years of experience since the installation of the first unit in 2011, the in-situ chlorine generators (formerly Pure Chlore) benefit from all our French know-how. It is the only in situ chlorine generator to be entirely designed and manufactured in France.

What is in-situ chlorine generation?

The Pool Technologie in-situ chlorine generators allow you to produce your chlorine on site from salt and softened water, in an economical way and in complete autonomy. This solution provides all the benefits of salt electrolysis without adding any salt to the pool. Indeed, the electrolysis cell is not integrated in the hydraulic circuit but housed in a reactor installed in the technical room. Only a chlorine solution is produced and stored in a secure storage tank. The salt content of the waste water is therefore negligible.

With more than 10 years of experience since the installation of the first unit in 2011, the in-situ chlorine generators (formerly Pure Chlore) benefit from all our French know-how. It is the only in situ chlorine generator to be entirely designed and manufactured in France.

- On-site production of fresh, constant concentration chlorine without degradation over time

- Less clogging of injection points due to the low mineral content of the solution produced

- Less chloramines

- Improved bathing comfort: crystal clear water, non-aggressed skin, non-irritated eyes

- Elimination of transport and storage of hazardous materials

- Elimination of handling of hazardous chemicals

- Elimination of chlorine vapour emissions

- Remote monitoring (Connect Pro, e-Pool)

- Easier commissioning

- Reduced and simplified maintenance: alarms by written message, easy access to sub-assemblies

- Integration on new or existing installations

- Reduced production costs: salt costs between 7 and 10 times less than chlorine (depending on whether it is liquid, pebble or powder). Production is optimised and energy costs are reduced

- Reduced labour costs

An operating principle perfectly suited

to private pools…

Control of the production reactor, management of production and pH set points,

Intuitive navigation on backlit LCD screen

Softened water tank to supply the brine tank and the production cell.

0.8 litre capacity

Brine tank isolated from the salt tank

Salt tank: the salt used must comply with one of the 4 standards below: NF EN 973 Quality A – NF EN 14805 Type 1 – NF EN 16401 Quality A – NF EN16370. Capacity of 2 x 25 kg bags of salt

Automatic injection of an optimal amount of brine and softened water at the entrance of the production circuit

The resulting mixture is injected into the production cell circuit. Sodium hypochlorite is thus produced continuously.

Long life cell (10,000 hours)

Cell maintenance alert: thanks to an hour counter, a message appears to warn the user of specific maintenance operations

The chlorine solution is directly injected into the pipe thanks to a suction pipe connected to the hydraulic circuit of the pool

Bluetooth control with the e-Pool application: setting of production and pH parameters, event history, updating of equipment software, sending of a report to the professional.

Total management of the technical room thanks to the e-Pool Connect application: setting and control of the technical room devices remotely (filtration, water treatment, lighting, robot, etc.), management of a pool park, remote alerts.

An operating principle perfectly suited

to private pools…

Control of the production reactor, management of production and pH set points,

Intuitive navigation on backlit LCD screen

Softened water tank to supply the brine tank and the production cell.

0.8 litre capacity

Brine tank isolated from the salt tank

Salt tank: the salt used must comply with one of the 4 standards below: NF EN 973 Quality A – NF EN 14805 Type 1 – NF EN 16401 Quality A – NF EN16370. Capacity of 2 x 25 kg bags of salt

Automatic injection of an optimal amount of brine and softened water at the entrance of the production circuit

The resulting mixture is injected into the production cell circuit. Sodium hypochlorite is thus produced continuously.

Long life cell (10,000 hours)

Cell maintenance alert: thanks to an hour counter, a message appears to warn the user of specific maintenance operations

The chlorine solution is directly injected into the pipe thanks to a suction pipe connected to the hydraulic circuit of the pool

Bluetooth control with the e-Pool application: setting of production and pH parameters, event history, updating of equipment software, sending of a report to the professional.

Total management of the technical room thanks to the e-Pool Connect application: setting and control of the technical room devices remotely (filtration, water treatment, lighting, robot, etc.), management of a pool park, remote alerts.

The supply of softened water to the reactor is mandatory and necessary for the proper functioning of the in-situ chlorine generator. The softener is optional.

Control of the production reactor, management of production and pH set points,

Intuitive navigation on backlit LCD screen

Softened water tank to supply the brine tank and the production cell.

0.8 litre capacity

Brine tank isolated from the salt tank

Salt tank: the salt used must comply with one of the 4 standards below: NF EN 973 Quality A – NF EN 14805 Type 1 – NF EN 16401 Quality A – NF EN16370. Capacity of 2 x 25 kg bags of salt

Automatic injection of an optimal amount of brine and softened water at the entrance of the production circuit

The resulting mixture is injected into the production cell circuit. Sodium hypochlorite is thus produced continuously.

Long life cell (10,000 hours)

Cell maintenance alert: thanks to an hour counter, a message appears to warn the user of specific maintenance operations

100 L tank with anti-UV treatment + retention tank: preservation of pure and fresh chlorine

Suction pipes: allows the suction of sodium hypochlorite

Level probes: high, low, overflow. Disconnectable for easy maintenance

Vent for evacuation of the hydrogen produced

… and collective use pools

The supply of softened water to the reactor is mandatory and necessary for the proper functioning of the in-situ chlorine generator. The softener is optional.

Control of the production reactor, management of production and pH set points,

Intuitive navigation on backlit LCD screen

Softened water tank to supply the brine tank and the production cell.

0.8 litre capacity

Brine tank isolated from the salt tank

Salt tank: the salt used must comply with one of the 4 standards below: NF EN 973 Quality A – NF EN 14805 Type 1 – NF EN 16401 Quality A – NF EN16370. Capacity of 2 x 25 kg bags of salt

Automatic injection of an optimal amount of brine and softened water at the entrance of the production circuit

The resulting mixture is injected into the production cell circuit. Sodium hypochlorite is thus produced continuously.

Long life cell (10,000 hours)

Cell maintenance alert: thanks to an hour counter, a message appears to warn the user of specific maintenance operations

100 L tank with anti-UV treatment + retention tank: preservation of pure and fresh chlorine

Suction pipes: allows the suction of sodium hypochlorite

Level probes: high, low, overflow. Disconnectable for easy maintenance

Vent for evacuation of the hydrogen produced

… and collective use pools

Fresh chlorine production

with a constant concentration and without degradation

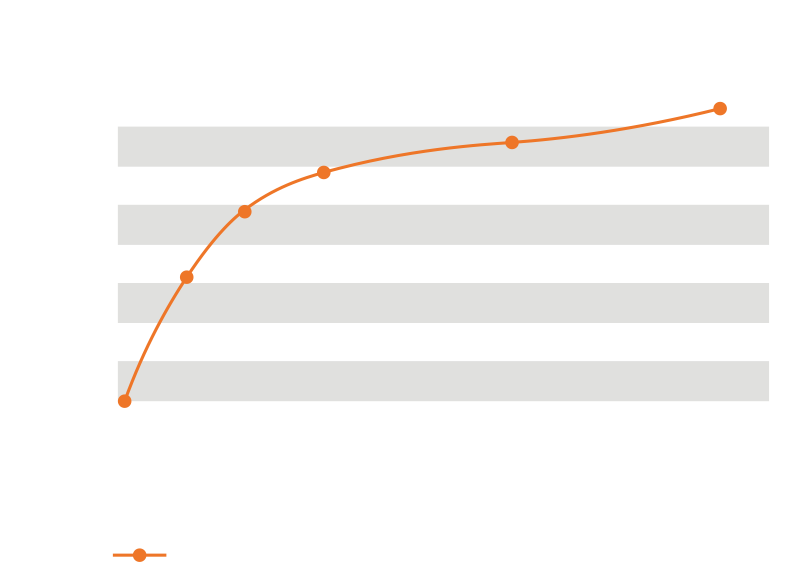

iPOQLOR® produces sodium hypochlorite or liquid chlorine (NaClO) with a concentration of between 1 and 4 g of active chlorine per litre depending on the model. This low concentration has multiple advantages:

- Due to its low mineral concentration, the sodium hypochlorite thus generated will significantly limit the scaling of the injection points.

- Its pH of 9 (whereas the pH of liquid chlorine is 12) will significantly reduce the use of acid to lower the pH of the pool

- Significant improvement in bathing comfort: crystal clear water, skin is not attacked and eyes are not irritated.

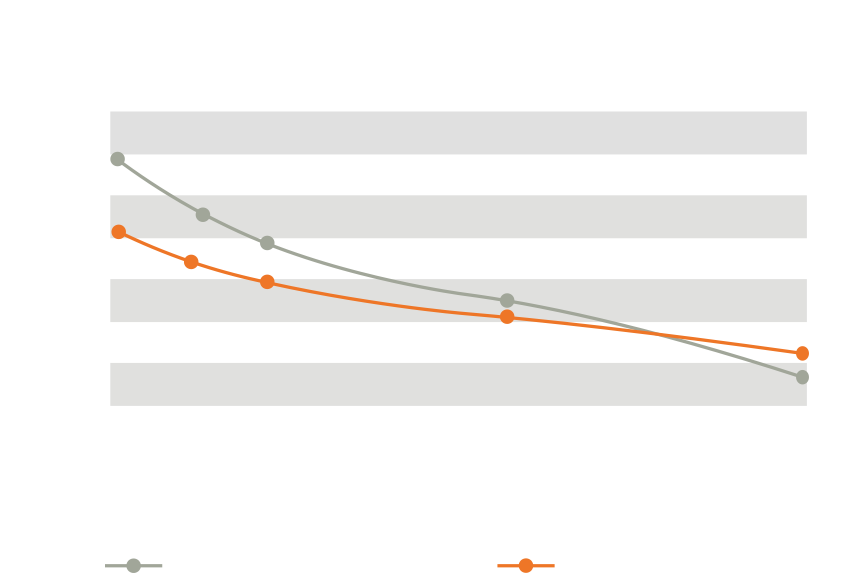

Storage time has a major influence on the loss of concentration of liquid chlorine, which can be as high as 50% after 30 days.

30 days. This loss of concentration will be amplified by a high storage temperature.

Over time, chlorine will generate by-products, some of which are harmful to human health, such as chlorates.

The length of storage and the initial concentration of active chlorine will significantly favour the formation of these by-products.

Fresh chlorine production

with a constant concentration and without degradation

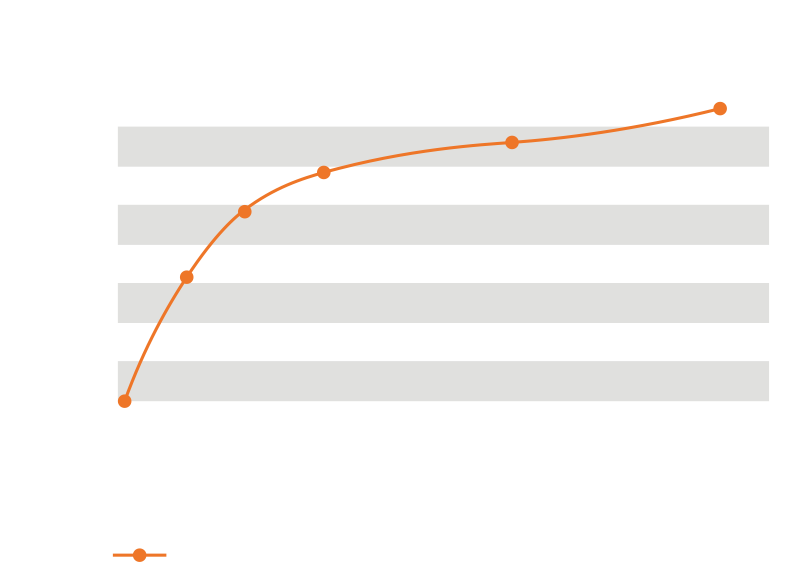

iPOQLOR® produces sodium hypochlorite or liquid chlorine (NaClO) with a concentration of between 1 and 4 g of active chlorine per litre depending on the model. This low concentration has multiple advantages:

- Due to its low mineral concentration, the sodium hypochlorite thus generated will significantly limit the scaling of the injection points.

- Its pH of 9 (whereas the pH of liquid chlorine is 12) will significantly reduce the use of acid to lower the pH of the pool

- Significant improvement in bathing comfort: crystal clear water, skin is not attacked and eyes are not irritated.

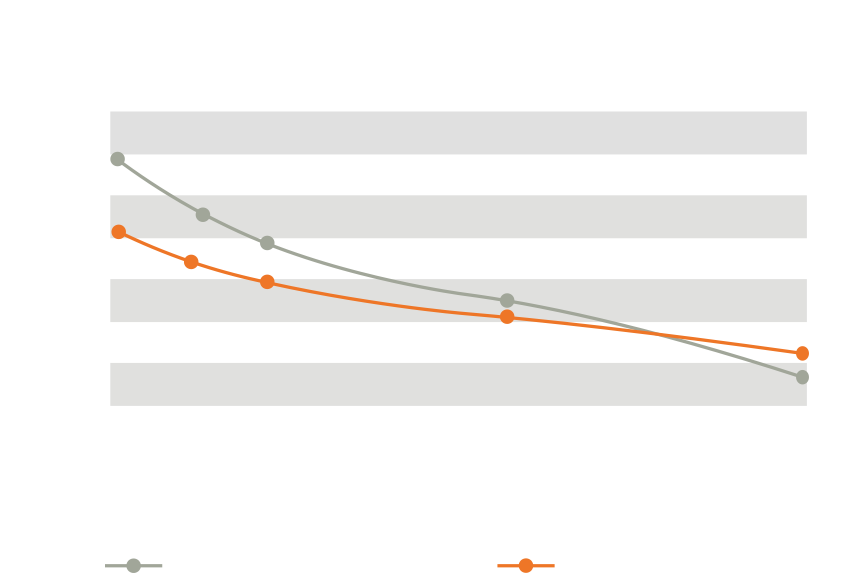

Storage time has a major influence on the loss of concentration of liquid chlorine, which can be as high as 50% after 30 days.

30 days. This loss of concentration will be amplified by a high storage temperature.

Over time, chlorine will generate by-products, some of which are harmful to human health, such as chlorates.

The length of storage and the initial concentration of active chlorine will significantly favour the formation of these by-products.