In situ chlorine generator by saltwater chlorination

In situ chlorine generator by saltwater chlorination

iPOQLOR® Compact: create your own chlorine!

The use of conditioned chlorine for the disinfection of collective swimming pools, whether it is liquid, solid or gaseous, has many drawbacks today:

• Dangerousness of the products

• Alteration of the quality of the chlorine over time

• High operating and transportation costs

• Regular maintenance of the installations

• Non-negligible environmental impact

iPOQLOR® Compact is a solution that provides all the benefits of salt electrolysis without adding any salt to the pool. Indeed, the electrolysis cell is not integrated in the hydraulic circuit but housed in a reactor installed in the technical room.

It is in this logic that iPOQLOR® was imagined. This solution provides all the benefits of salt electrolysis without adding any salt to the pool. Indeed, the electrolysis cell is not integrated in the hydraulic circuit but housed in a reactor installed in the technical room.

iPOQLOR® can be used in all types of public pools:

Aquatic centers, municipal pools, hotels, campgrounds, condominiums ect…

iPOQLOR® Compact: create your own chlorine!

The use of conditioned chlorine for the disinfection of collective swimming pools, whether it is liquid, solid or gaseous, has many drawbacks today:

• Dangerousness of the products

• Alteration of the quality of the chlorine over time

• High operating and transportation costs

• Regular maintenance of the installations

• Non-negligible environmental impact

iPOQLOR® Compact is a solution that provides all the benefits of salt electrolysis without adding any salt to the pool. Indeed, the electrolysis cell is not integrated in the hydraulic circuit but housed in a reactor installed in the technical room.

It is in this logic that iPOQLOR® was imagined. This solution provides all the benefits of salt electrolysis without adding any salt to the pool. Indeed, the electrolysis cell is not integrated in the hydraulic circuit but housed in a reactor installed in the technical room.

iPOQLOR® can be used in all types of public pools:

Aquatic centers, municipal pools, hotels, campgrounds, condominiums ect…

iPOQLOR® Compact can be used in all types of public pools:

Public pools, campings, hotels

Aquatic centres

Para-medical

iPOQLOR® Compact can be used in all types of public pools:

Public pools, campings, hotels

Aquatic centres

Para-medical

Discover the future of saltwater chlorination! Follow our Youtube channel to find out more videos:

Discover the future of saltwater chlorination! Follow our Youtube channel to find out more videos:

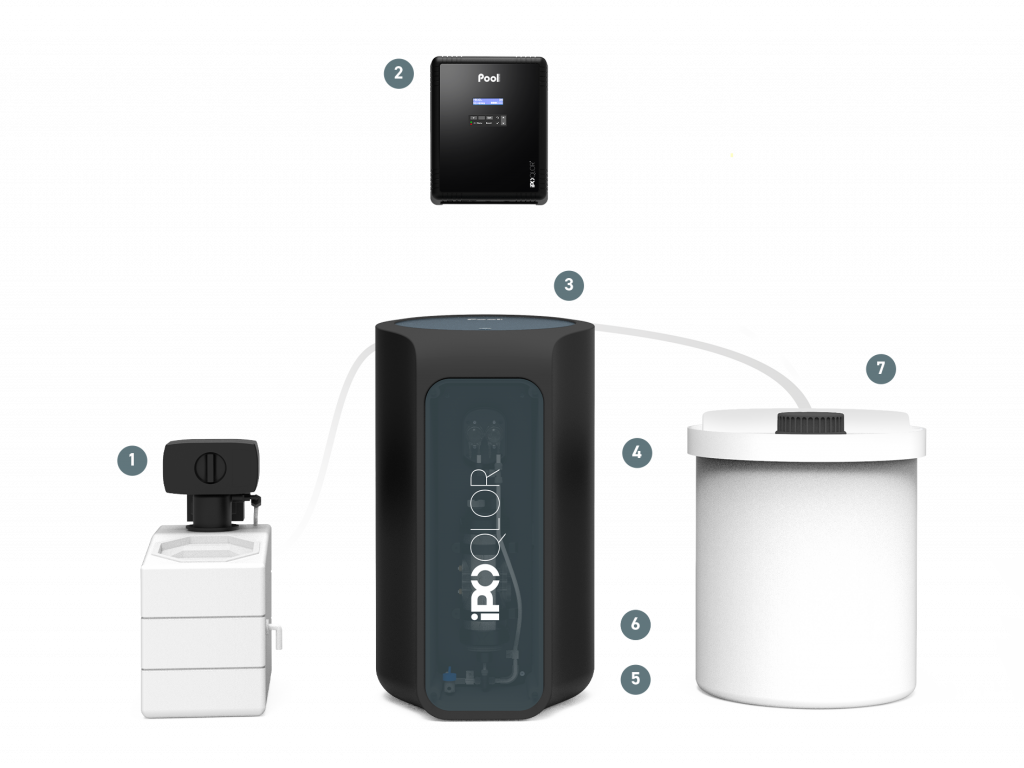

A simple and efficient principle!

1 – Softener

The supply of softened water to the reactor is mandatory and necessary for the proper functioning of iPOQLOR® (otpion softener)

2 – Control and production box

Control of the production reactor, management of tank filling levels and production ranges. Intuitive navigation on blacklit LCD screen

3 – Production reactor

Softened water tank to supply the brine tank and the production cell (0.8 liter capacity)

Brine tank isolated from the salt reserve

Salt tank: the salt used must comply with one of the four NF EN standards: NF EN 973 Qualité A – NF EN 14805 Type 1 – NF EN 16401 Qualité A – NF EN16370

4 – Pumps

Automatic injection of an optimal quantity of brine and softened water at the entrance of the production circuit

5 – Circuit input

The resulting mixture is injected into the production cell circuit. Sodium hypochlorite is thus produced continuously

6- Production cell

Long life cell (10 000 hours). Cell maintenance alert thanks to an hour counter, a message appears to warn the user of specific maintenance operations

7- Sealed production tank

100L tank with anti-UV treatment + retention tank for pure and fresh chlorine preservation

Suction canes wich allows the aspiration of sodium hypochlorite

Level high, high, low, and overflow probes. They can be disconnected for easy maintenance

Product hydrogen evacuation event

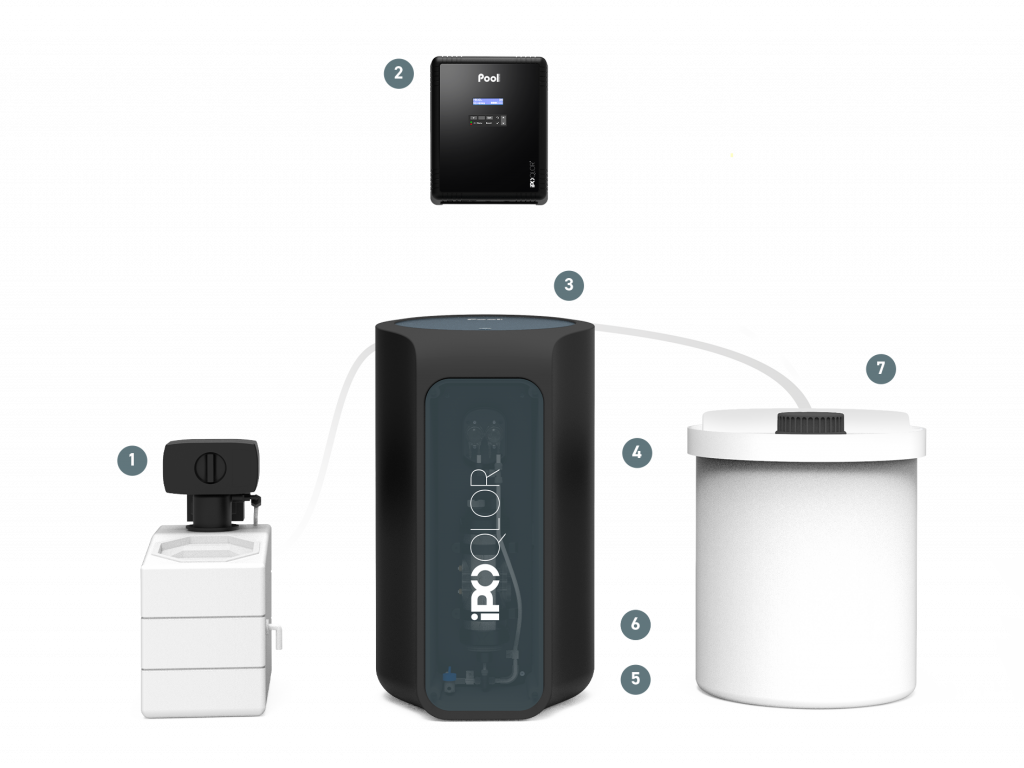

A simple and efficient principle!

1 – Softener

The supply of softened water to the reactor is mandatory and necessary for the proper functioning of iPOQLOR® (otpion softener)

2 – Control and production box

Control of the production reactor, management of tank filling levels and production ranges. Intuitive navigation on blacklit LCD screen

3 – Production reactor

Softened water tank to supply the brine tank and the production cell (0.8 liter capacity)

Brine tank isolated from the salt reserve

Salt tank: the salt used must comply with one of the four NF EN standards: NF EN 973 Qualité A – NF EN 14805 Type 1 – NF EN 16401 Qualité A – NF EN16370

4 – Pumps

Automatic injection of an optimal quantity of brine and softened water at the entrance of the production circuit

5 – Circuit input

The resulting mixture is injected into the production cell circuit. Sodium hypochlorite is thus produced continuously

6- Production cell

Long life cell (10 000 hours). Cell maintenance alert thanks to an hour counter, a message appears to warn the user of specific maintenance operations

7- Sealed production tank

100L tank with anti-UV treatment + retention tank for pure and fresh chlorine preservation

Suction canes wich allows the aspiration of sodium hypochlorite

Level high, high, low, and overflow probes. They can be disconnected for easy maintenance

Product hydrogen evacuation event

A complete range for all you need!

A complete range for all you need!

A solution for all your projects

Complete your iPOQLOR® Compact solution with Pro Dosing® Ampero or Pro Dosing® ORP (automatic dosing system) for a more efficient disinfection. Equipped with amperemotric or ORP probe, it regulates the chlorine rate to inject into the pool. A predictive and proportionnal regulation complete the disinfection.

Our teams will help you choose the model best suited to your needs by conducting a technical study. On-site or in-plant training is also available. Depending on the needs of your installation, iPOQLOR® can be accompanied by a dosing panel, Pro Dosing® ORP or Ampero for a more efficient disinfection.

A solution for all your projects

Complete your iPOQLOR® Compact solution with Pro Dosing® Ampero or Pro Dosing® ORP (automatic dosing system) for a more efficient disinfection. Equipped with amperemotric or ORP probe, it regulates the chlorine rate to inject into the pool. A predictive and proportionnal regulation complete the disinfection.

Our teams will help you choose the model best suited to your needs by conducting a technical study. On-site or in-plant training is also available. Depending on the needs of your installation, iPOQLOR® can be accompanied by a dosing panel, Pro Dosing® ORP or Ampero for a more efficient disinfection.

Local service

Local service

You have a project?

Contact our sales department!

contact@pool-technologie.fr

You have a project?

Contact our sales department!

contact@pool-technologie.fr